Demand control kitchen ventilation offers more than just energy savings – How to utilize sensor data in property management

Demand control ventilation has become an important part of energy efficiency in many properties. It can significantly reduce energy consumption, especially for heating, by adjusting ventilation according to the usage rate of the spaces.

In office spaces, demand control ventilation often optimizes airflow based on carbon dioxide levels or temperature, as these metrics provide sufficiently accurate information about occupancy and the number of people in the space, and thus the need for ventilation.

In commercial kitchens, more advanced sensors are needed. Simple sensor data is not enough to assess ventilation needs because ventilation must be adjusted according to the activities in the kitchen, not just the number of people present.

In kitchens, ventilation is typically sized based on kitchen equipment: different types of equipment, such as ovens or fryers, have specific airflow requirements that are used to calculate the total required airflow for the kitchen.

Determining the correct airflow is always a balance between energy efficiency and maintaining good indoor air quality, as kitchen usage can vary greatly on different days and seasons. When this challenge is combined with the large amounts of air required for kitchen ventilation – up to thousands of liters per second – it is clear that there is a significant need for energy-efficient ventilation solutions in commercial kitchens. More than two-thirds of energy consumption in commercial kitchens typically goes to ventilation and heating (source: Motiva: Energy-Efficient Commercial Kitchens).

Demand control ventilation offers several advantages over traditional timer-based ventilation solutions:

- Energy savings: By adjusting ventilation based on actual needs, unnecessary energy consumption can be avoided.

- Flexibility: The system easily adapts to different use cases, such as varying opening hours and seasonal changes, without the need for manual adjustments.

- Data utilization: Sensor data can be used to make more informed decisions about space usage and improve energy efficiency.

Advanced sensor technology offers new opportunities in property management

A bottleneck in implementing demand control kitchen ventilation has been the need for sufficiently advanced sensor technology that takes into account the specific requirements of the space, such as the use of kitchen equipment and changes in air quality in different situations.

The Finnish kitchen technology pioneer Safera Oy has responded to this challenge by developing a demand control kitchen ventilation system specifically optimized for professional kitchen environments.

Safera’s FlowHero demand control kitchen ventilation monitors the use of kitchen equipment and workstations as well as air quality through various sensors and determines what is happening in the kitchen and how ventilation should be adjusted. For example, when vegetables are being chopped, the need for ventilation is lower than when stir-fry dishes are being prepared on a tilt skillet.

In commercial kitchens, the energy savings from demand control kitchen ventilation can pay back the investment in a few years. In addition to energy savings, demand control kitchen ventilation also enhances property management. Because commercial kitchens require more advanced sensor technology than is suitable for office spaces, the data collected is much more versatile, allowing for comprehensive analyses of space usage.

The following are some concrete examples of how sensor data from demand control kitchen ventilation can be utilized in property management. The examples are drawn from real cases in lunch and hotel restaurants.

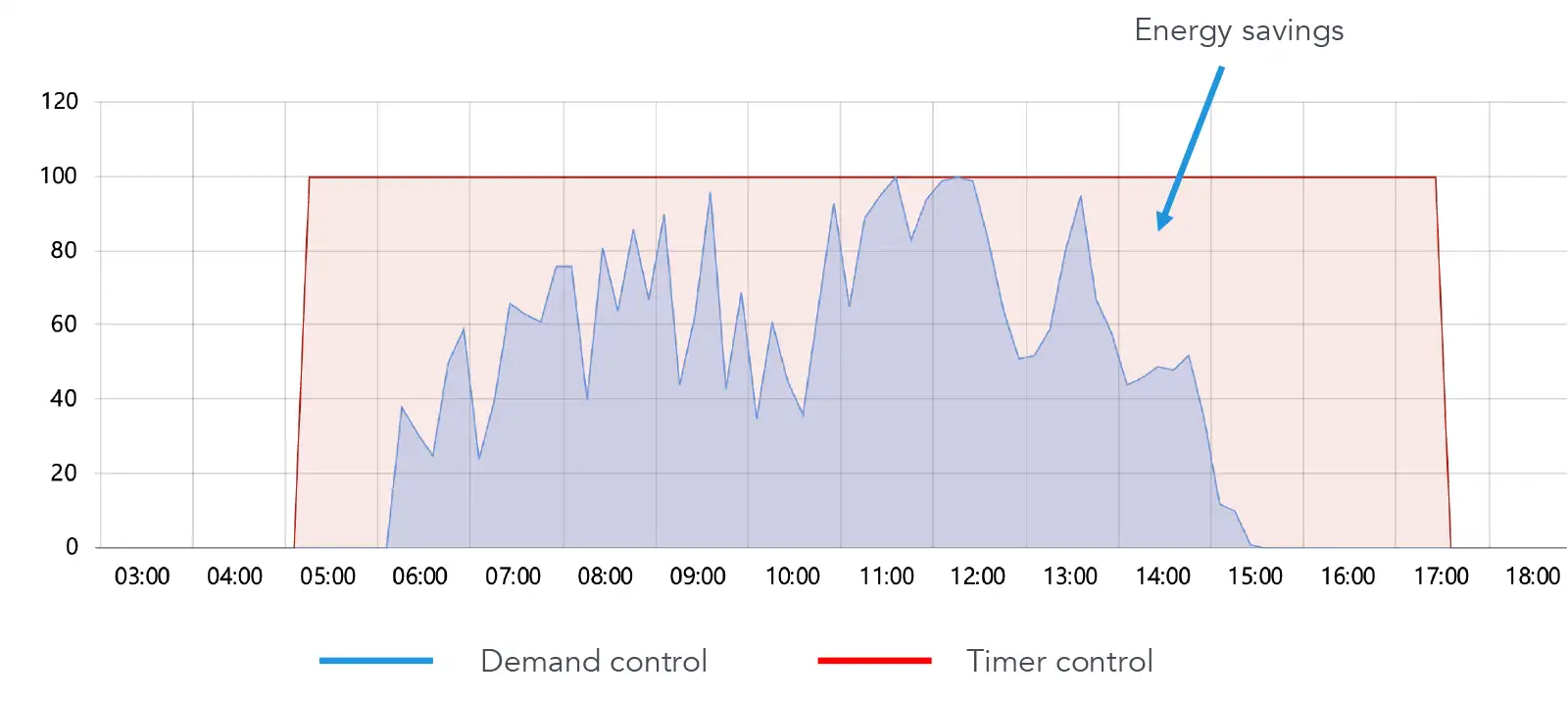

Comparing timer-controlled and demand control ventilation provides insights into space usage and highlights where energy savings come from

The energy savings from demand-controlled ventilation can be verified by comparing the ventilation control curves of timers and demand control. This comparison helps property owners understand how ventilation works in relation to space usage. The comparison shows when the kitchen opens and closes, how its usage rate varies throughout the day, and how demand control optimizes the airflow during the day.

Sensor data reveals energy waste from the timer's weekly program

In one office building, a comprehensive energy efficiency project was undertaken, where ventilation timers were optimized based on airflow requirements and design documents. However, after installing demand-controlled ventilation in the restaurant, data revealed that the previously optimized timer program still resulted in significant energy waste.

Demand control reduced the ventilation volume by up to 87% compared to timer control.

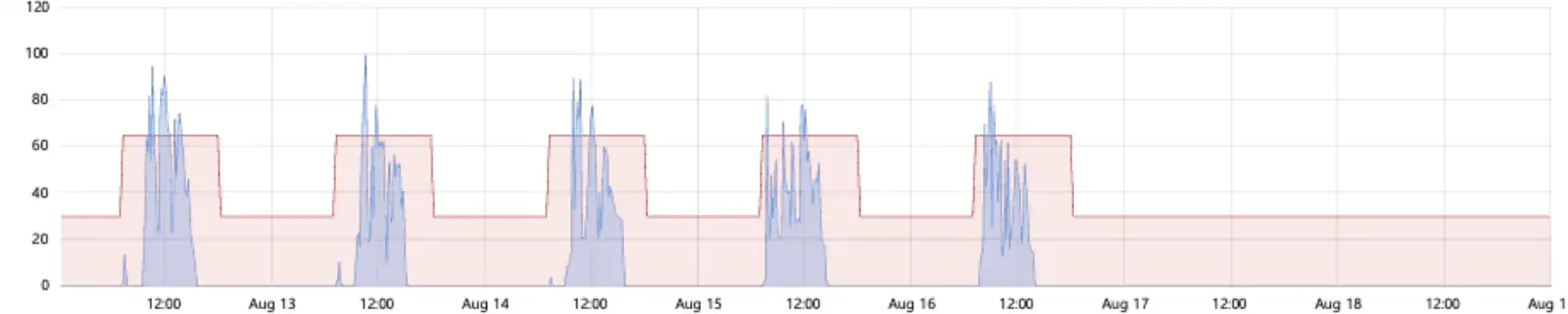

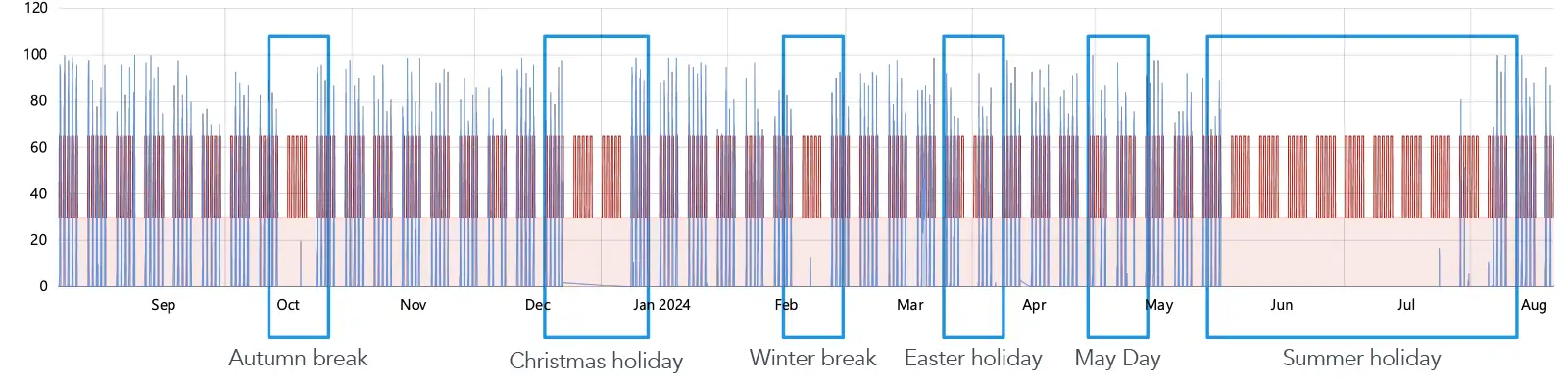

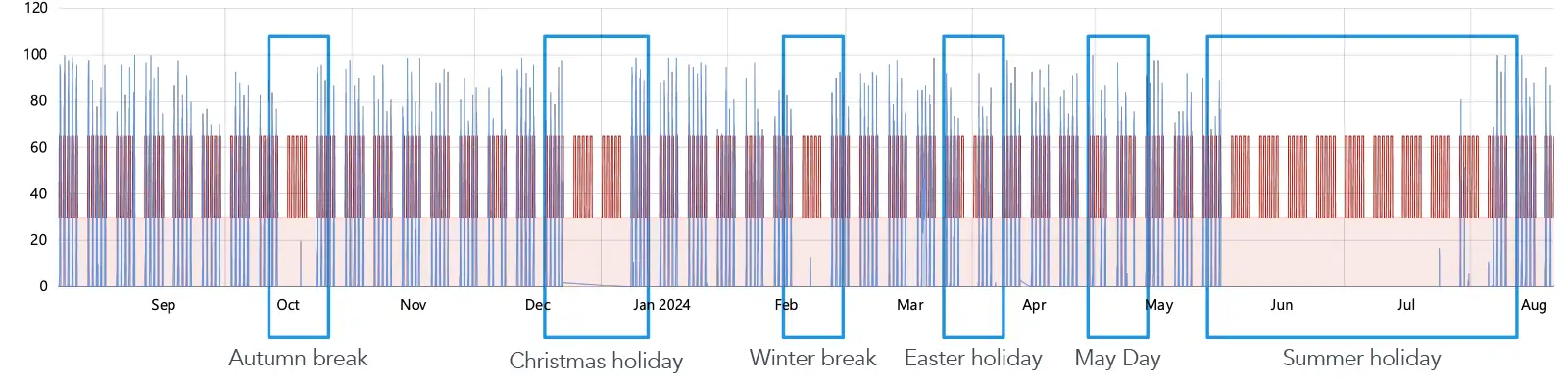

Holidays and public holidays can cause significant energy waste

Timers often follow a weekly schedule that does not account for holidays or public holidays, leading to significant energy waste. Continuously optimizing the timer according to holiday schedules is challenging because these dates vary annually, and kitchen opening hours may vary during holiday seasons.

Demand control automatically ensures that when the kitchen is closed, the ventilation is also turned off or operated at minimal power. If the kitchen is in use, demand control optimizes the ventilation to ensure good indoor air quality without requiring manual adjustment by staff.

In hotel restaurants, the ventilation needs vary significantly throughout the day, making it difficult to save energy with a timer

In hotel restaurants, food is served from morning to evening, from early breakfast to late evening snacks almost every day of the year.

During the day, and depending on the season, kitchen usage levels vary, which often means that timer-controlled ventilation must be set to the maximum airflow rate for the entire day. The timer unnecessarily expels thousands of liters per second of heated air even when the kitchen is underutilized between meals and during quieter periods.

With demand control ventilation, the airflow can be optimally adjusted at all times, saving energy.

The timer's boost setting was not enough to prevent steam from the dishwashing area from spreading into the dining room

In one lunch restaurant, the ventilation was controlled by a timer, which was not sufficient to prevent steam from spreading from the dishwashing area to the dining room. The use of a timer did not solve the problem because the need for additional boosting was irregular, and at other times it would have significantly increased energy waste.

Demand control allows for increasing ventilation only when the dishwashing area requires it the most, thereby saving energy and improving indoor air quality in the dining room.

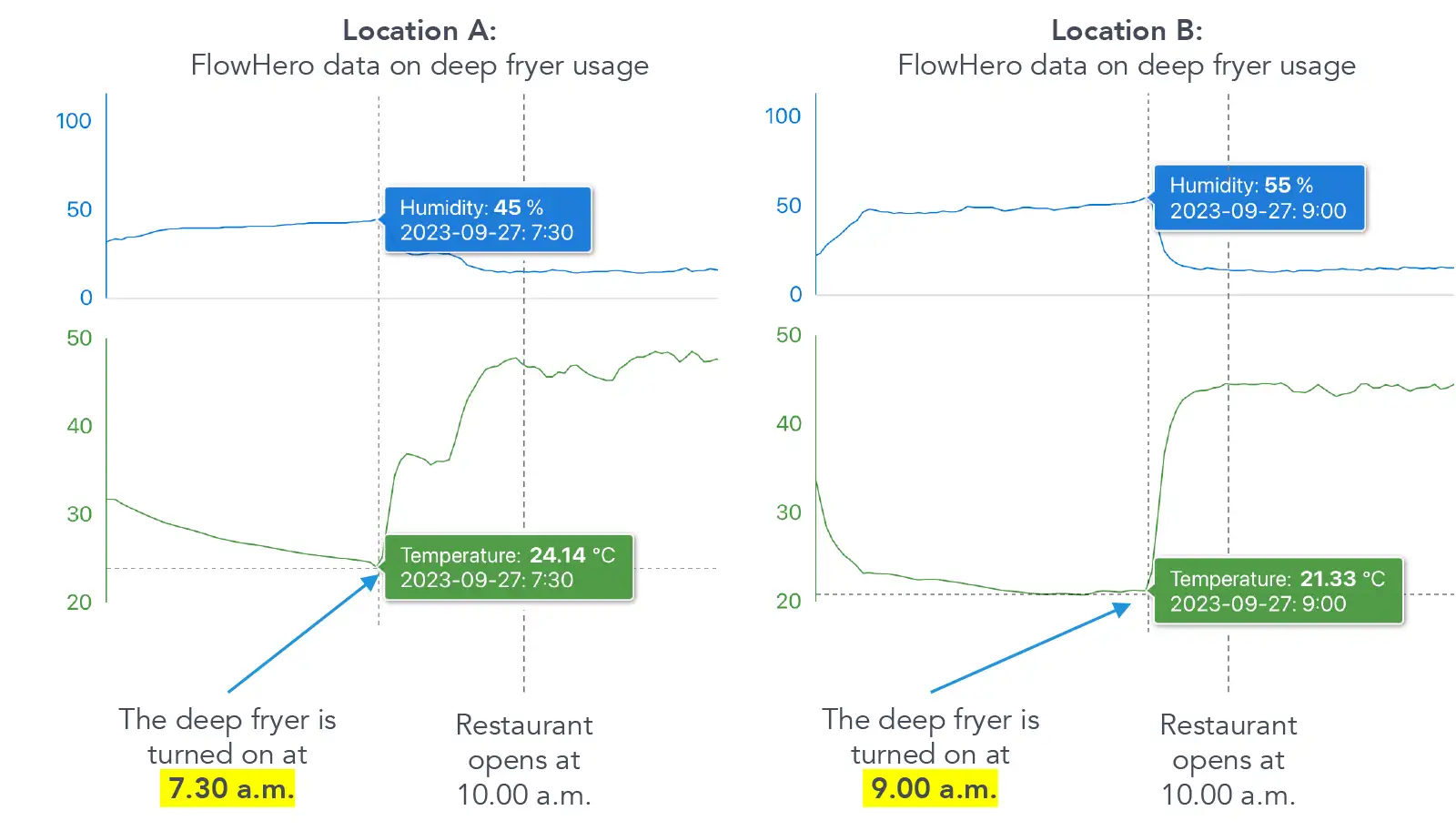

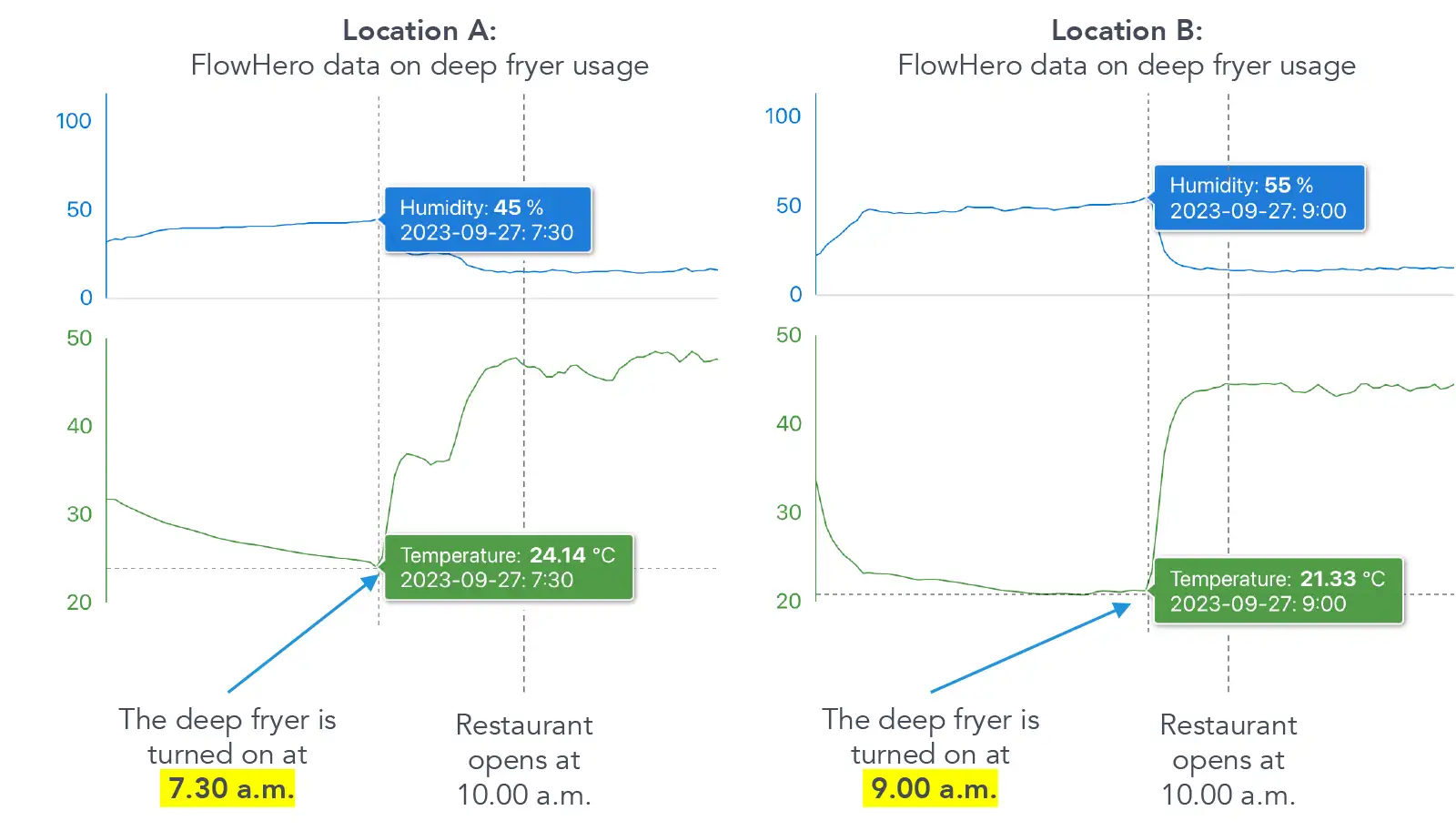

Data reveals differences in kitchen equipment usage between locations: in one, the deep fryer is turned on 1.5 hours earlier than necessary

In two similar locations of a restaurant chain, there was a 20 kWh deep fryer. Sensor data revealed that at location A, the fryer was turned on 2.5 hours before the restaurant opened, while at location B, it was turned on 1 hour before opening at 10:00 AM. If this happens daily, location A wastes approximately 10,950 kWh of energy per year (365 days x 1.5 hours x 20 kWh). This could be prevented by instructing staff on the correct usage of equipment.

A discussion with the restaurant revealed that one location had recently experienced a staff change, which resulted in changes to kitchen equipment usage practices.

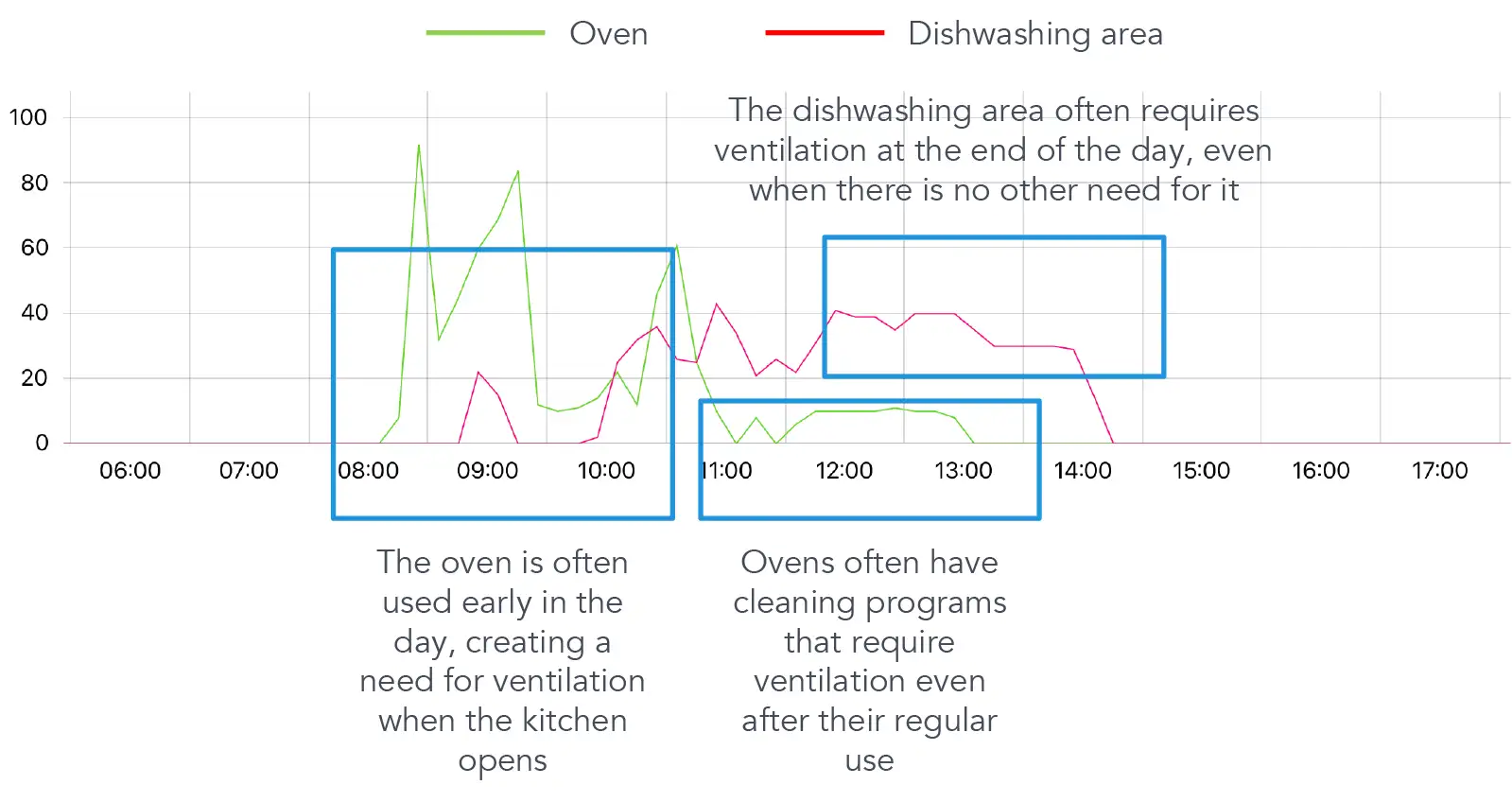

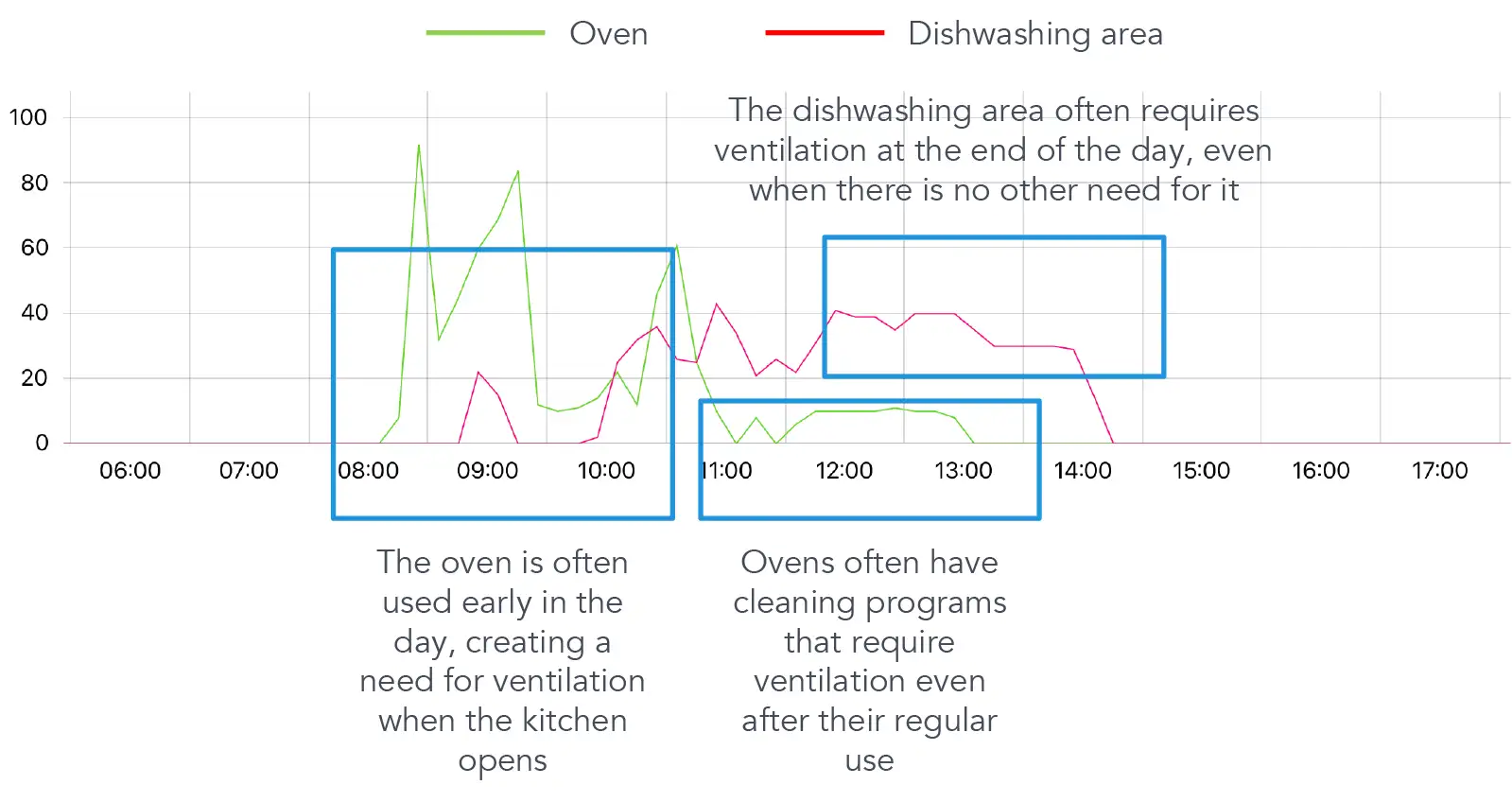

Separating ventilation for the dishwashing area increases energy savings

In many places, kitchen equipment and the dishwashing area require ventilation at different times, necessitating increased ventilation for longer periods. By separating the ventilation for the dishwashing area from the kitchen area, the ventilation for both areas can be independently optimized using demand control, leading to additional energy savings.

Summary

Demand-controlled ventilation in commercial kitchens not only reduces energy consumption but also provides valuable sensor data on space usage and indoor air quality. This data enables more accurate analysis and helps optimize ventilation based on actual needs. As a result, property management becomes more flexible and efficient, enhancing both energy efficiency and user experience. Sensor data enables data-driven decisions that support comprehensive property management and sustainable development.

See also:

FlowHero Case Study: Castellum Piispanhuippu

FlowHero demand control kitchen ventilation (DCKV) system clearly exceeded expectations at Piispanhuippu: kitchen air volume decreased by 67% (target 40%) and the payback period improved

FlowHero Case Study: Metos Personnel Restaurant

Metos, the Nordic leader in professional kitchen solutions, chose FlowHero DCKV for its own staff restaurant. The automated ventilation system delivers concrete energy savings and